Find Name Plate Punching Machine, Cnc Tube Punching Machine, What Is Cnc Punching Machine on Industry Directory, Reliable Manufacturer/Supplier/Factory from China.

New Products

| Payment Type: | L/C,T/T,D/P,Paypal,Money Gram,Western Union |

|---|---|

| Incoterm: | FOB,CFR,CIF,EXW |

| Min. Order: | 1 Set/Sets |

| Delivery Time: | 30 Days |

Model No.: TPP103

Applicable Industry for PLATES Punching Machine:

This cnc steel plates punching machine is the special equipment used for punching and marking of connection plates in the field of steel tower, bridge, steel structure.

Product Feature of cnc plates punching machine:

1. The machine-frame is made by C-type Plate welding, with good rigidity and big handling space. The machine sets three die-stations (two punching, one marking), automatic switching die-stations. Clamping system can be adapted to different workpiece, with reference block, and workpiece supported by rolling-ball working table. X & Y axis action controlled by servo motor and ball-screw driving and PLC, control the position of punching, so as to make the whole machining process automatically. Operator input the workpiece program, it can be used repeatedly

2. Adopt CNC technology, servo motor infeeding, with high efficiency, stable workpiece precision.

3. Important functional components adopt modular assembly, easy to repair it.

4. Achieve punching and marking on the one plate.

5. Easy programming, can read CAD drawing and also can use the program generated by lofting software. It can ready TEKLA lofting software files, such as NC1 format.

6. With self-diagnosis failures function.

7. X, Y axis are driven by servo motor + ball screw + linear guide, the precision is better.

Specifications of Plate Punching Machine:

| Model | TPP103 | TPPR103 |

| Max size of work piece L×W(mm) | 1500×800 | |

| Max. punching diameter (mm) | Φ26 | |

| Plate punching thickNess (mm) | 5~25 (Q235) | 5-25 (Q345),5-20(Q420) |

| Punching force (kN) | 1000 | 1200 |

| Marking force (kN) | 800 | 1000 |

| Min. distance between hole and plate edge (mm) | 25 | |

| Character size(mm) | 14×10×19 | |

| Qty. of character | 12 | 16 |

| Die-stations | 3 | |

| Programming mode | Auto CAD or lofting software | |

| Overall dimensions L×W×H (mm) | About 3200×3000×1900 | About 3400×3200×1900 |

| Machine weight (Kg) | About 5420 | About 6500 |

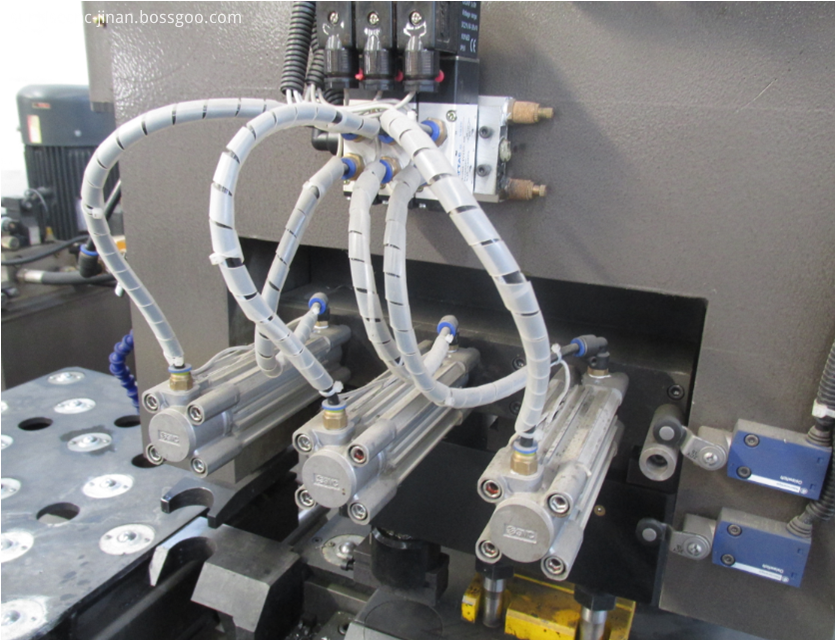

The Punching Unit - Three position - One for marking, two for punching

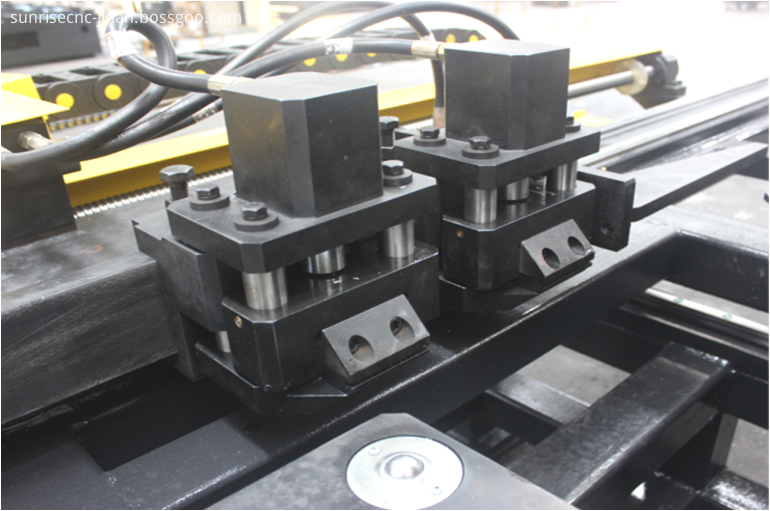

The Work Table and The Hydraulic Clams

The Work Table and The Hydraulic Clams

The Manual Lubrication System:

Now we equipped the machine with manual lubrication system, previous client need to lubricate the punching and marking dies one by one, now they just need push the handle, it can lubricate the punching and marking dies simultaneously. The operator don`t need reach out to the inside of machine, It`s more convenient and more security.

Our Service of punching machine:

Installation:

The seller shall send one engineer to the buyer's country for installation, commissioning and training. The buyer is responsible to provide all necessary equipments for handling and lifting the machine parts before seller's engineers go to the buyer's plant. In addition, the buyer should provide workers to support in installation activities, under supervision from the seller's engineers.

Commission:

The Supplier should give drawings and other details of material/preparation required for installation of machinery which the buyer has to prepare and keep ready before the machine arrives at the buyer's factory. Installation and commissioning can be finished within 5-10 days for above machine generally.

Training:

Training will include training on computer programming, machine operation and troubleshooting. The training time is at most 5 days for this machine. The buyer should arrange no less than two people for accepting training. After training, the buyer should sign the "Receiving & Inspection Report" supplied by the seller to demonstrate the successful finish of commissioning and acceptance of the buyer.

Contact us if you need more details on Name Plate Punching Machine. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Cnc Tube Punching Machine、What is Cnc Punching Machine. If these products fail to match your need, please contact us and we would like to provide relevant information.

Product Categories : Punching Machine > Plate Punching Machine